Lobe Pump Advantages and Disadvantages

Lobe pumps are versatile and widely used in various industries, thanks to their unique design and operational characteristics. In this comprehensive guide, we will delve into the advantages and disadvantages of lobe pumps. Whether you are considering purchasing one or simply seeking to expand your knowledge, this article will provide you with the insights you need.

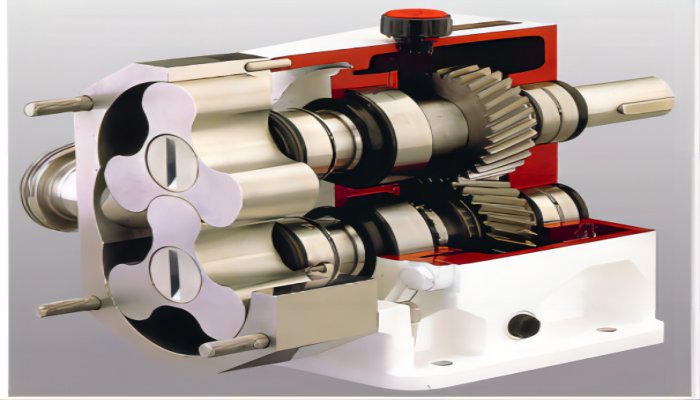

Understanding Lobe Pumps

Before we explore their pros and cons, let's start with a brief overview of what lobe pumps are. Lobe pumps are positive displacement pumps that use two rotating lobes, or gear-like elements, to move fluids. These lobes create a synchronized, non-contacting pumping action that makes them suitable for handling a wide range of viscous and non-viscous fluids, including food products, chemicals, and more.

Advantages of Lobe Pumps

Now, let's dive into the advantages of using lobe pumps in various applications:

1. Versatility

Lobe pumps can handle a broad spectrum of liquids, including those with high viscosity and solids content. This versatility makes them ideal for industries such as food processing, pharmaceuticals, and wastewater treatment.

2. Gentle Product Handling

The non-contacting lobes of these pumps ensure gentle product handling, making them suitable for shear-sensitive fluids. This is especially critical in the food and beverage industry, where product quality is paramount.

3. Self-Priming

Lobe pumps are typically self-priming, meaning they can evacuate air from the suction line and create a strong vacuum. This feature reduces the risk of cavitation and ensures efficient operation.

4. High Efficiency

Their positive displacement design leads to consistent flow rates, which can be crucial in processes where precision is essential. Additionally, lobe pumps are known for their energy efficiency.

5. Ease of Maintenance

These pumps are relatively easy to maintain due to their simple design and minimal moving parts. This results in reduced downtime and lower maintenance costs.

Disadvantages of Lobe Pumps

While lobe pumps offer numerous benefits, they also come with some drawbacks that should be considered:

1. Cost

Lobe pumps can be more expensive upfront compared to some other types of pumps. However, their long-term efficiency and reliability often offset this initial cost.

2. Limited Solids Handling

While lobe pumps can handle solids to some extent, they are not as well-suited for heavy solids handling as certain other pump types, such as diaphragm pumps or peristaltic pumps.

3. Maintenance Requirements

Although lobe pumps are generally easy to maintain, they do require regular attention to seals and lubrication to prevent wear and potential leakage.

4. Complex Cleaning

In some applications, cleaning lobe pumps can be more complex due to their design. This can be a challenge in industries with strict hygiene standards.

In Conclusion

In summary, lobe pumps offer a wide range of advantages, including versatility, gentle product handling, and high efficiency. However, they also have their disadvantages, such as initial cost and limited solids handling capability. Choosing the right pump for your specific application requires careful consideration of your unique requirements and priorities.

If you are looking for a pump that excels in handling viscous fluids, provides consistent flow rates, and is easy to maintain, lobe pumps may be an excellent choice. However, for applications involving heavy solids or where cost is a primary concern, it's essential to weigh the advantages and disadvantages carefully.

Ultimately, the decision to use lobe pumps should align with your specific needs and industry demands, ensuring optimal performance and cost-effectiveness.

Indonesian

Indonesian