Vacuum Homogenizer Mixer

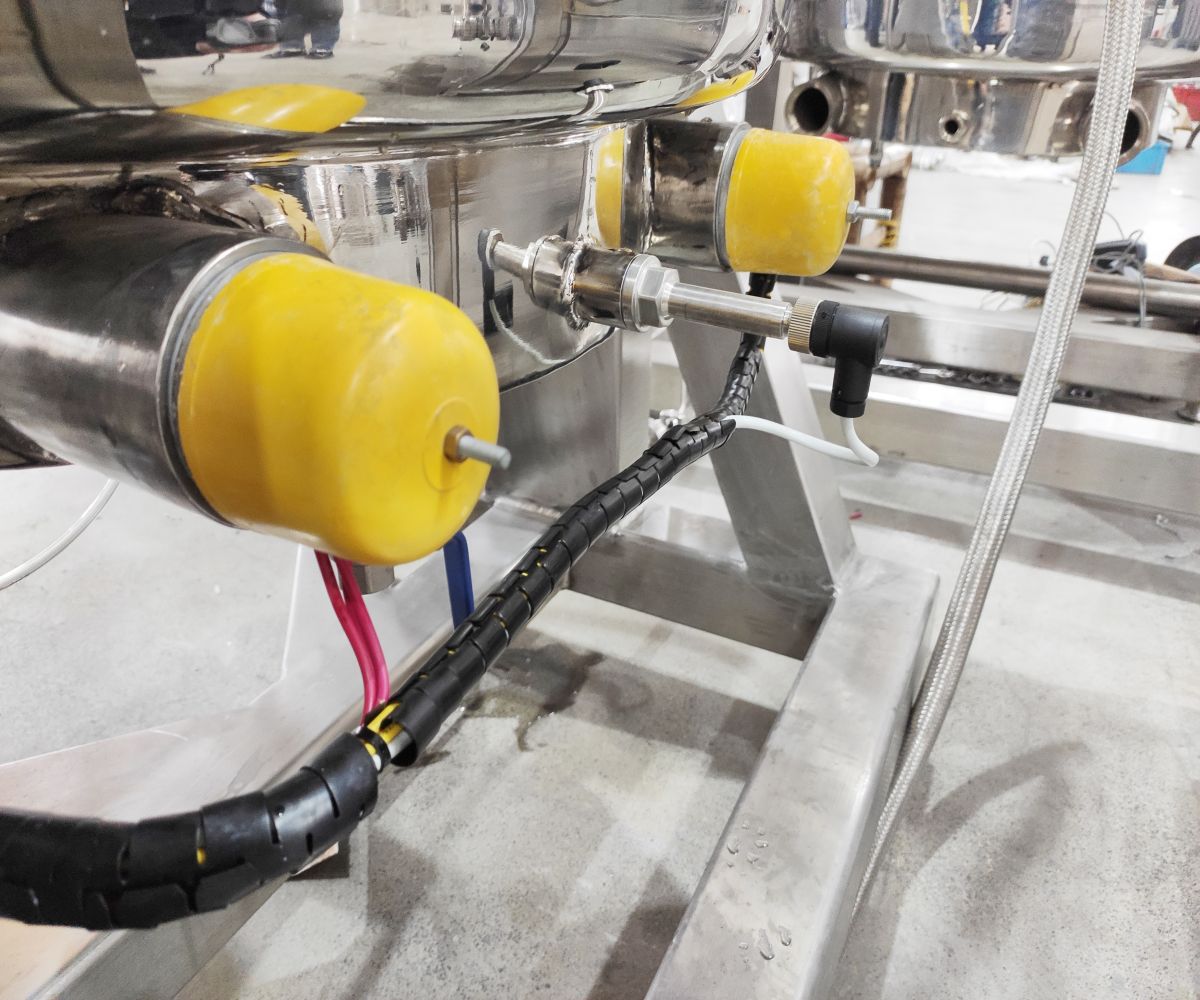

LOB's Vacuum Homogenizer Mixer – a cutting-edge solution that revolutionizes cream and emulsion production. Esteemed as a premier choice, this vacuum emulsifier homogenizer has garnered popularity in both Asian and US markets for its exceptional design and functionality. Tailored for crafting small to medium batches of creams and emulsions, it's the pinnacle of innovation.

Key Features:

- Operating capacity ranging from 50L to 2,000L;

- Ideal for creams and emulsions with viscosities between 10,000 and 50,000cps;

- Efficient internal emulsification and homogenization facilitated by a top-mounted batch homogenizer..

[Usage and Benefits]

- Triple Agitator System: Uniquely equipped with three agitators - wall scraper, paddle, and Homogenizer - ensuring thorough blending and dispersion.

- Effortless Viscosity Handling: Designed to handle creams and emulsions with viscosities ranging from 10,000 to 50,000cps.

- Optimized Mixing Action: Employs a top-mounted batch homogenizer for efficient internal emulsifying and homogenizing.

- Integrated Vacuum System: Equipped with a vacuum system to eliminate air and enhance product homogeneity.

- Capacity: 50 l to 2000 l

- Motor Power: Look the sheet below

- Construction: Material: Stainless steel 304 or SS316L

- Control System: Intuitive touchscreen for easy operation or button control

- Motor Type: Three-phase electric motor

Vacuum homogenizer mixer: Technical Specifications

| Working capacity (L) | Agitator power (kw) | Speed (rpm) | Homogenizer power (kw) | Speed (rpm) | Oil/Water tank (L) | Agitator power (kw) | Speed (rpm) |

|---|---|---|---|---|---|---|---|

| 50 | 1.5 | 0~50 | 4 | 0~3600 | 30/30 | 0.25/0.25 | 960 |

| 100 | 1.5 | 0~50 | 4 | 0~3600 | 50/70 | 0.37/0.37 | 960 |

| 150 | 1.5 | 0~50 | 4 | 0~3600 | 80/100 | 0.55/0.55 | 960 |

| 200 | 1.5 | 0~50 | 4 | 0~3600 | 100/130 | 0.75/0.75 | 960 |

| 250 | 2.2 | 0~50 | 5.5 | 0~3600 | 120/160 | 0.75/0.75 | 960 |

| 300 | 2.2 | 0~50 | 5.5 | 0~3600 | 150/200 | 0.75/0.75 | 960 |

| 350 | 2.2 | 0~50 | 5.5 | 0~3600 | 170/220 | 1.1/1.1 | 960 |

| 400 | 3.7 | 0~50 | 7.5 | 0~3600 | 190/250 | 1.1/1.1 | 960 |

| 500 | 3.7 | 0~50 | 7.5 | 0~3600 | 250/300 | 1.1/1.1 | 960 |

| 600 | 3.7 | 0~50 | 7.5 | 0~3600 | 280/350 | 1.5/1.5 | 960 |

| 750 | 5.5 | 0~50 | 11 | 0~3600 | 350/450 | 1.5/1.5 | 960 |

| 1000 | 5.5 | 0~50 | 15 | 0~3600 | 450/650 | 2.2/2.2 | 960 |

| 1500 | 7.5 | 0~50 | 18.5 | 0~3600 | 650/1000 | 2.2/2.2 | 960 |

| 2000 | 7.5 | 0~50 | 18.5 | 0~3600 | 800/1400 | 2.2/3 | 960 |

Image Gallery

[User Guide]

- Connect to the appropriate power source.

- Activate the touchscreen and set the required parameters.

- Place cosmetic ingredients into the provided container.

- Utilize the lifting and tilting feature to facilitate filling and material pouring.

- Monitor the homogenization process via the touchscreen and ensure high-quality homogenized results.

- Ensure stable power supply when using the device.

- Read the user guide carefully before operating the device.

- For further assistance, please contact our customer support team.

- Package Includes: user manual, 24/7 customer support

- Warranty: 1-year full warranty

Indonesian

Indonesian